Hello Everyone,

Here's another progress update on the emonTx SMT design.

This week I've sent the PCB CAD design files off to get a few prototype PCB's made. It's a very exciting moment, quite a milestone but also nerve wrecking! These prototypes will be assembled by hand and tested extensively. Eventually we plan to get the board ready assembled using factory SMT pick-and-place machines, selling the emonTX SMT as a kit is not an option! We don't plan to discontinue the current through-hole emonTx, we believe there is value in having a simpler through-hole kit version as an option.

It will be sometime before emonTx SMT's are rolling off the production line, there are many hoops which need to be jumped through before then, but getting the first prototype off the ground is a good step forward!

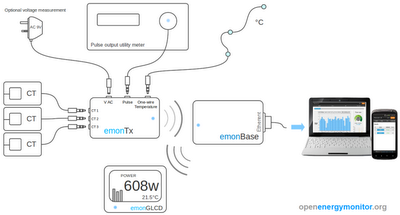

As a quick re-cap the main features of the emonTx SMT are:

- Improved accuracy when monitoring low power levels with a programmable gain op-amp input stage on the CT inputs..see blog post

- Single power supply - Half-wave rectifier AC-DC circuit to power the unit (under basic operation) and monitor mains voltage (enabling real power readings) from a single AC-AC PSU..see blog post

- Direct USB programming - No USB to UART or FTDI cable required - built in USB host using the ATmega32u4 building on Arduino Leonardo design.

- On-board Ethernet and multiple wireless radio options – RFM12B will remain the default option.

- Pluggable-terminal block - Pulse-counting input, 2 x one-wire temperature inputs and other spare I/O broken out on a pluggable-terminal block.

- Casing - designed to fit in a nice wall-mountable extruded aluminium case with laser cut fascias and external SMA antenna.

For more info, design notes and my general ramblings see my forum post...