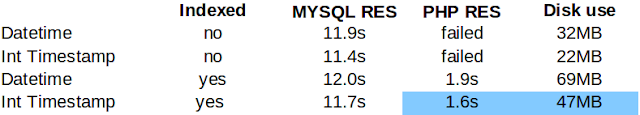

Heat loss from a hot water cylinder should be proportional to the temperature differential between the inside and the outside of the cylinder by a constant: Watts of heat loss per kelvin. See heat conductivity.

Watts of heat loss can be calculated from the temperature reduction per unit time of the average cylinder temperature. If we plot heat loss against average cylinder temperature we should get a linear relationship where the slope of the line of best fit is the heat loss factor, see graph 2 below.

This constant the heat loss factor for a particular cylinder is a useful measure in evaluating the performance of a cylinder.

My hot water is heated with a 3kW electric immersion heater. I wanted to know how much heat would be lost if I leave the immersion heater on all the time at a given temperature and so how much energy I could save by only putting the immersion heater on specifically when its needed i.e for a bath in the evening.

The results

I have selected a period of time here where both hot water and the immersion heater where not used. Leaving only solar hot water heat input and heat loss from the cylinder as the only drivers of the system. The solar hot water coil is in the bottom of the cylinder which heat's the cylinder relatively evenly compared with the immersion heater making it ideal for this test. I have filtered out all positive heat gain so that we can see the heat loss clearly:

Conclusion

The conclusion is that we are saving about 1.6 kWh/d from reduced heat loss (30C temperature difference over 23 hours), which is a good saving from something relatively easy to do. It may be that we are saving more than this from reduced hot water demand in the first place by not having hot water on tap all day but this is another thing to test.

If your monitoring hot water cylinder temperature It would be great to see how these figures compare.

Download the source code: heatloss.zip