Over the past few months we have been working with John Cantor to develop, build and test the potential of a heat pump monitoring system. John has a lifetimes experience of installing, optimising and troubleshooting all types of heat pumps. John runs heatpumps.co.uk and has recently written a very informative book Heat Pumps for the Home.

The rest of this post will be a guest post by John, over to you:

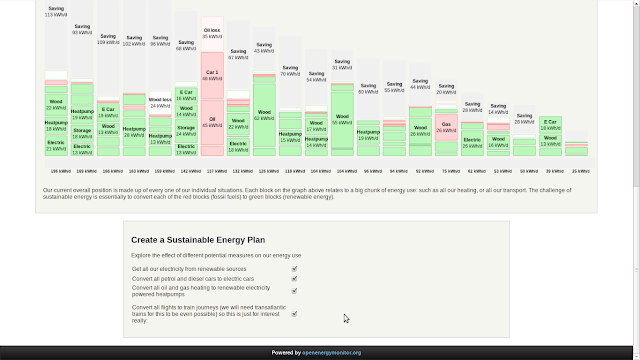

A heat pump works by transferring heat form one place to another. The electrical input power should be only a fraction (maybe

1/3rd or 1/4) of the available heat delivered. However, the energy efficiency can vary dramatically. One of the biggest factors that affect this is the working temperatures on the cold (source) and the hot (sink) sides of the system. This is mainly dictated of system design (radiators/underfloor-heating details etc), but it is also dependent on the way that the system is operated, see

www.heatpumps.co.uk

It has become evident that a significant number of the UK’s heat pumps are not reaching their energy-efficiency potential. In ordered for us to learn how best to install, set-up and operate heat pump systems, some form of real-time monitoring is vital.

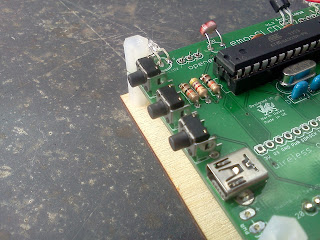

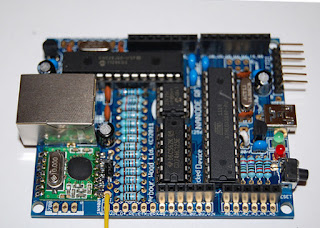

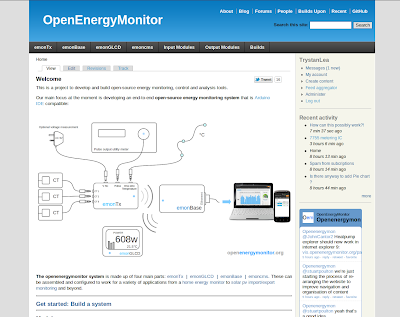

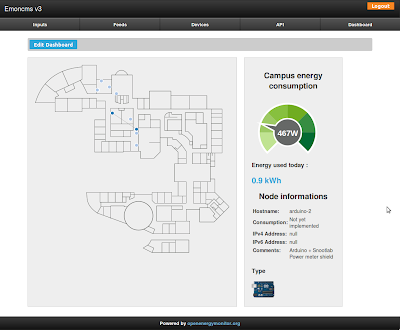

We have developed a heatpump-specific variant of the OpenEnegyMonitor wireless web-connected emonBase and emonTx system. Emoncms was used as the web logging and graphing application.

This tool is as valuable as the stethoscope and X ray is to a doctor. It allows a heating system to be analysed in detail and observed over time so that settings can be modified, use-patterns changed, and system modifications be made.

Our first test was on a heat pump in Scotland. The owner initially had some very high electricity bills. After a brief spell of monitoring, we were able to pinpoint a few issues.

These related to the electric boost heater coming on unnecessarily and the under-floor heating poorly balanced causing frequent compressor ‘cycling’ (stop/start). However, this installation was generally a good example. The data can be seen here:

http://vis.openenergymonitor.org/pages/heatpump.php

Our second test was on a suspect system in Wales. This showed up some alarming temperatures on the source, and it is apparent that the refrigeration circuit is in poor health. We plan to repair the system, then compare the graphs before and after.

The graphs below show just one aspect of the analysis.

There are many things that can be viewed using the web-dashboard. This includes the refrigeration circuit, the source, the underfloor heating and the compressor power-factor.

It seems likely that there would be 2 main uses for this monitoring.

1) For the installer or technically-minded owner to learn how best to operate their system, or to pinpoint any areas for attention and possible modification.

2) For the owner to see some basic data relating to running cost etc. It would also be used as a remote monitor for holiday accommodation.

The diagram at the top shows the full version, but we are working on a simpler version that focuses on the user-control aspect of a system.