Ethical and Sustainable Electronics

The choices we make as consumers do make a difference, the stuff we buy accounts for about 40% of our current energy consumption, this is for the average person, it's probably a fair bit higher for 'techies'! The energy used to make the stuff we buy is more than the energy we use for personal transport and more than our energy demands for heating and cooling [1 – P.94]. Hi-tech electronic items have a large embodied energy carbon footprint and often contain 'conflict materials' such as gold (contacts) , tantalum (capacitors), tungsten etc. Manufacturing a PC requires 11 times it's own weight in raw materials to produce compared to 1-2 times for a car [1 - P.94]

|

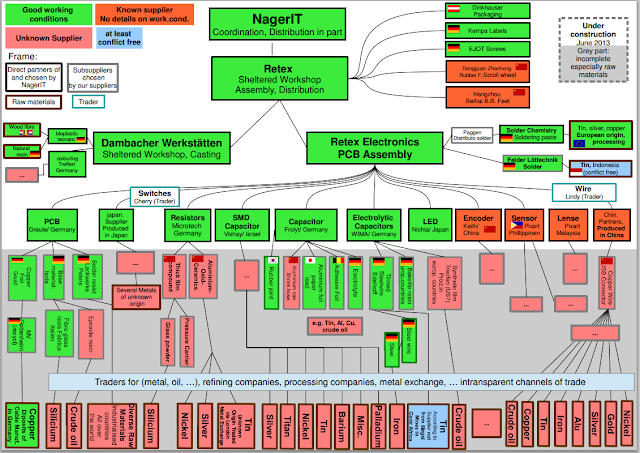

| Fair Trade Graphic from Nager IT |

In many areas of purchasing there is an ethical and lower carbon choice available, like buying local vegetables and fair trade coffee and chocolate etc. However when purchasing electronic items I have always assumed there was not this option, that no product is more ethical or lower carbon than another (they are all just as bad!).

I would like to highlight two projects that I have discovered lately that are working together to try and improve the state of electronics manufacture. I should state that I have no connection with these projects other than reading their websites.

The first is a German project called Nager-IT who have produced a "Faire Maus" or Fair Mouse.

They have designed the USB mouse using low carbon materials and have gone to great lengths to source ethically produced components and have pushed for transparency throughout the supply chain (something which is almost non existent in electronic production at the moment). Checkout this graphic they have produced illustrating their transparent supply chain:

The mouse they have produced can be purchased through their website.

The second project is called FairPhone, they are a social enterprise in the Netherlands with the aim of " designing, creating and producing our first smartphone and taking the next crucial step in uncovering the story behind the sourcing, production, distribution and recycling of electronics." They are developing and aiming to start stating in Autumn this year a 'fairer' android powered smartphone.

|

| Graphic from http://www.fairphone.com website |

It's uplifting to hear of small independent companies taking on the big players in the consumer electronics industry by offering a 'fairer' alternative. We as consumers should do our best to show that there is demand for more ethically produced electronic projects.

I have also discovered that GreenPeace produce an independent ranking of the large electronic companies based on how 'green' they are.

|

| Graphic from GreenPeace |

[1] – Sustainable Energy Without the Hot Air – David MacKay [2009]

How this relates to OpenEnergyMonitor

Steps we have taken so far

- Choose RHOS and components which are free of conflict materials

- Choose low embodied energy materials for enclosures which can be easily recycled

- Use standard parts which can be easily re programmed and used for other purposes in the future

- Use recyclable packaging (paper bags which are naturally antistatic) for our shipping

- Choose low power equipment, LED lighting, recycled paper for our office and switch things off at the end of the day!

- Choose surface freight (boat) rather than planes to ship stock (mainly power adapters) from China, this takes 3 months rather than 3 days but worth it for the 32 times less energy consumed [1 - P.92].

- Choose a PCB manufacture who are based in the UK who uses lead free techniques, complies to the highest environmental industry standard and is actively investing in techniques and equipment to reduce wastage and environmental impact (e.g water treatment and recycling)

- Strive to optimise electrical consumption in our hardware to be as low was possible

Steps we would like to take in the future

- Produce an end-to-end supply chain map of our manufacture (possibly using http://sourcemap.com)

- Try and calculate the embodied energy that goes into producing our designs and constantly try and find ways we can reduce this

- Sell through local distributors to reduce air based shipping and investigate possibility of local manufacture

- Use recycled plastic / other low embodied energy martial in the moulding of the housing for our next version of the emonGLCD and temperature monitoring node

- Investigate how we can build recyclability into the design, checkout the video below from the Great Recovery Project: