Earlier this week I visited Miles Hodkinson who runs Ciseco.

Ciseco supply us with the Open Kontrol Gateway web-connected base station, however Ciseco are best known for their range of wireless modules based on the Texas Instruments CC1110 chip. Most of Ciseco's products are manufactured by themselves in the UK. It was a fascinating visit to see the manufacturing process in action. I took a few photos which might be of interest to those of your who are interested in how things are made.

The surface mount electronics assembly process has got three main stages:

1. Apply solder paste on the PCB pads, this is done using a scraper and carefully aligned laser cut stencil.

|

| Solder pate application |

2. The pick and place machine places the SMT components in their correct locations and orientation on the board

|

| Pick and place - the components are supplied on the white reels |

3. After a quick visual check the board with the placed components is put in the reflow oven for a precise amount of time at a carefully monitored temperature profile. This melts the solderpaste and solders the components into place.

|

| Reflow Oven |

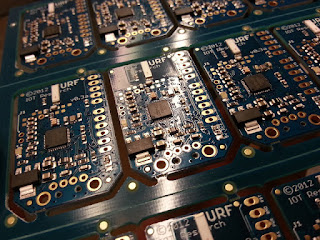

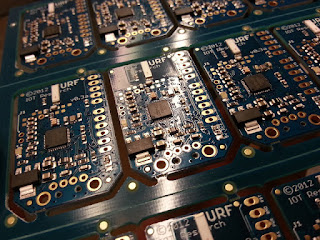

The finished boards are then taken away to be flashed, tested then finally the through-hole components such as the antenna socket are soldered on by hand.

|

| The finished boards |

View the full galley of photos including some videos of the pick and place in action:

To engage in discussion regarding this post, please post on our Community Forum.