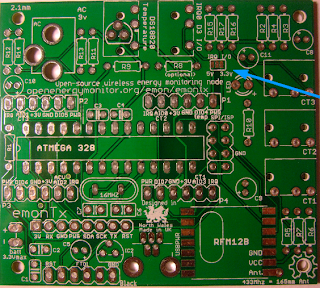

New emonTx PCB

The main changes are the addition of a footprint to enable a DS18B20 digital-temperature sensor to be soldered directly onto the board. The can be used instead of connecting an external DS128B20 temperature sensor using a 3.5mm jack.

The other change is the addition of a voltage select solder jumper for the IRQ pulse counting input which also doubles as a digital I/O port (Arduino Dig3). This solder jumper must be connected to either 3.3V (emonTx internal voltage) or 5V (if emonTx is powered via 5V usb). Routing 5V to the Vcc pin on this pulse IRQ port is useful when interfacing directly with pulse-output utility meters or controlling 5V relays. 3.3V works fine when using a TSL257 optical sensor to detect pulses from a pulse output LED.

|

| Front |

We have also added an area to note which frequency RFM12B modules has been soldered on, since once soldered on there is no way to telling! RFM12B frequency has become more important with the release of the NanodeRF which comes shipped with 868Mhz modules. OpenEnergyMonitor has in the past used 433Mhz modules; we now use modules of both frequencies. It's important to remember to use the correct length antenna for the frequency (details here) and set the correct frequency of the modules in the sketch.

| Rear We are on schedule to open an OpenEnergyMonitor online shop in the new year. If you're interested getting your hands on an emonTx then please fill in the interest form and we'll get back to you: emonTx interest form open-hardware emonTx PCB designs are up on solderpad The priority in the new year is to get custom encloses manufactured for the emonTx. Currently we have been drilling our own holes in a generic case for the connectors. If you can help us or have experience in designing and manufacturing electronic enclosures please get in touch. Likewise if you have any ideas for improvements or new features for the emonTx then please start a discussion in the hardware section of the forums. We love to hear all ideas. Merry Christmas everyone! |